FROM POWDER TO PERFORMANCE

HANA Advanced Material Technology

FROM POWDER TO PERFORMANCE

HANA Advanced Material Technology

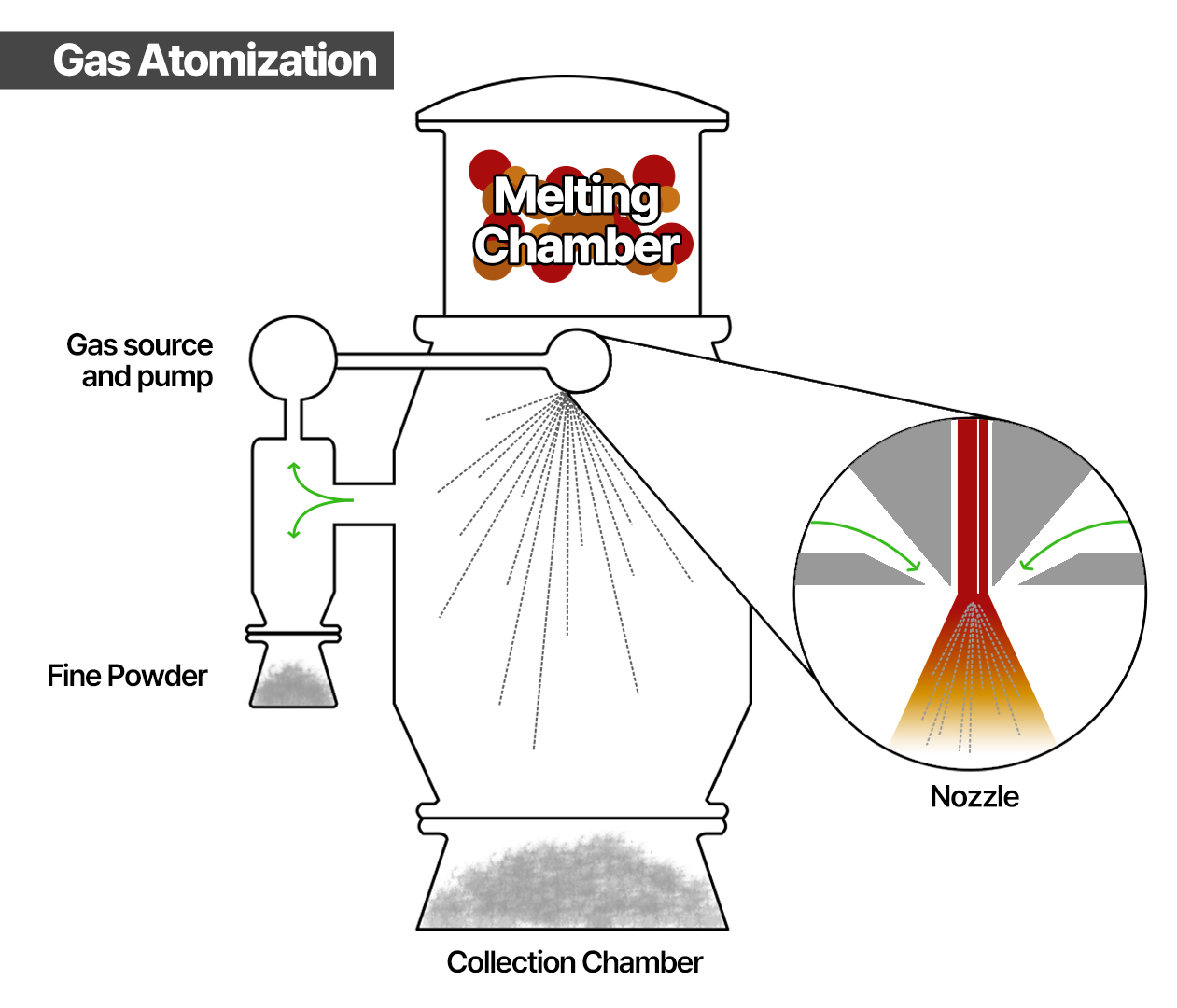

Gas Atomization (Gas Atomization Process) is one of the most common methods for manufacturing metal powders, which is a process for manufacturing fine powders by ejecting gas into molten metal.

During the gas atomization process, metal powders are obtained when the high pressure gas jets from the nozzle gives the strong impact energy to molten metal droplets during their fall through the orifice.

The changes of the factors such as gas type and pressure, internal diameter of orifice and nozzle type have an effect on the major characteristics such as powder properties, shapes and particle size distribution.

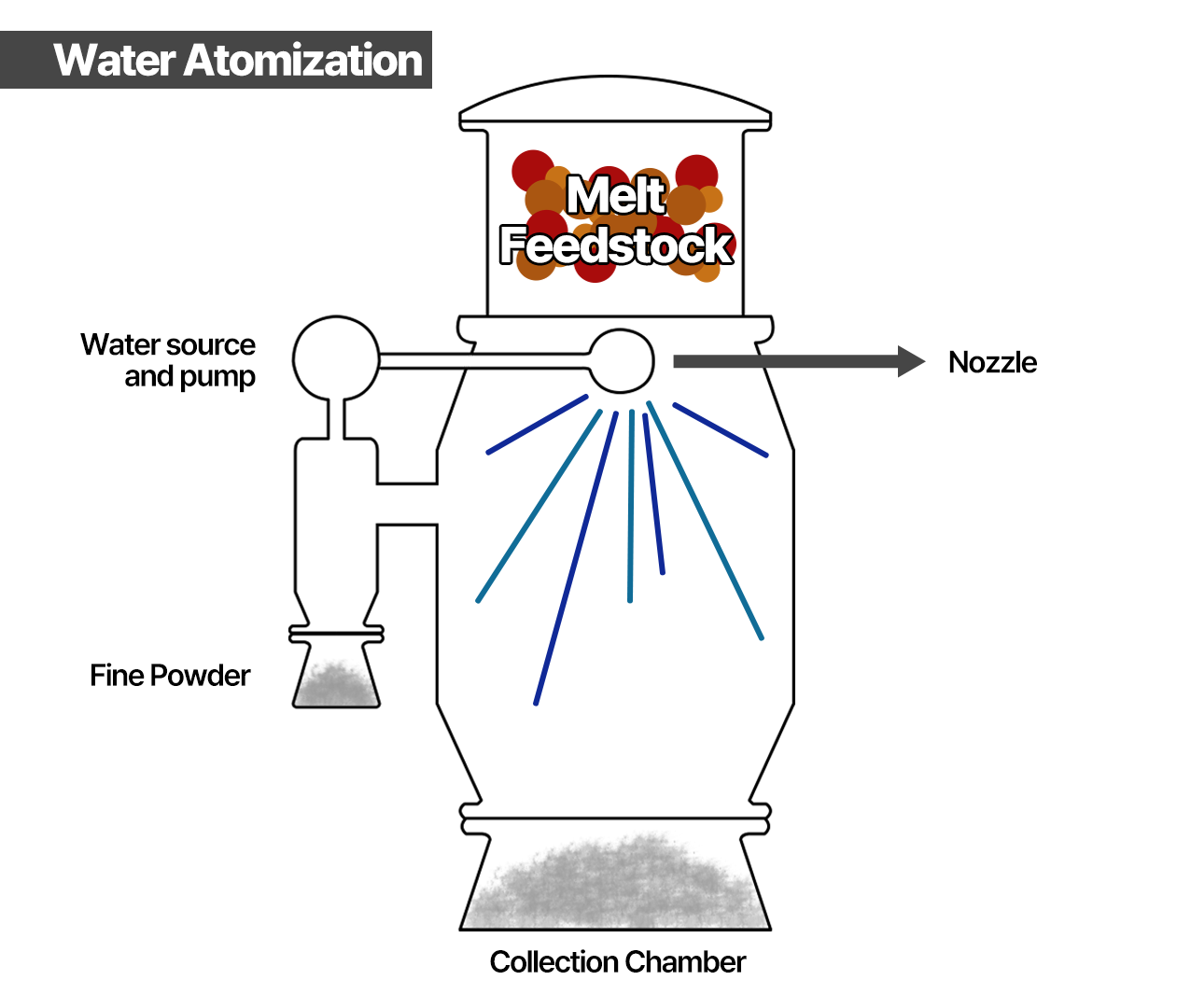

Water Atomization (Water Atomization Process) is one of the most common methods for irregular atomized powders, which is a process for manufacturing fine powders by ejecting gas into molten metal.

High-pressure water atomization has proven to be a viable, low-cost process to achieve fine particle size distributions for iron, stainless and low-alloy metal powders. The economic advantages and pre-alloying capability provide desirable advantages over competing technologies. Previous shortcomings relative to powder characteristics, i.e. irregular particle shape, lower tap densities, oxidized surfaces, have been refined to more closely replicate gas atomized powder properties.

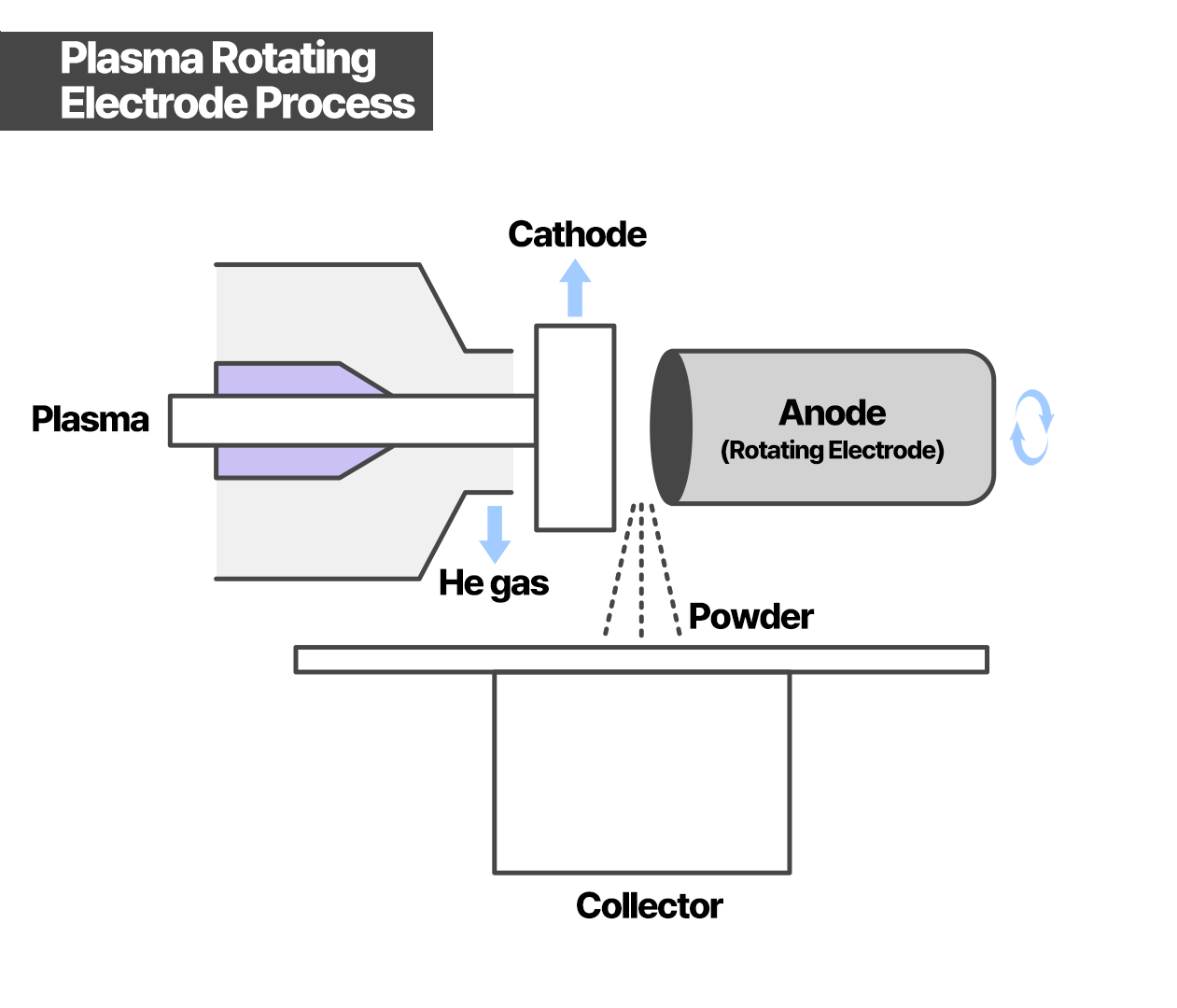

Metal or alloy are made into consumable electrodes as feedstock. The feedstock is heated by plasma torch and melt into molten liquid, then the molten is ejected by the centrifugal force of high-speed rotating electrode, crushed into small droplets and solidified into powders.

It used for producing high melting and alive metal powders, such as nickel-based or Ti-based alloy powder. It’s also suitable for producing various alloy powders, such as steel, cobalt, chromium, etc.

The atomized powders is of regular shape, high sphericity, bright surface and good fluidity. Also, there’s no satellite phenomenon and hollow powder.

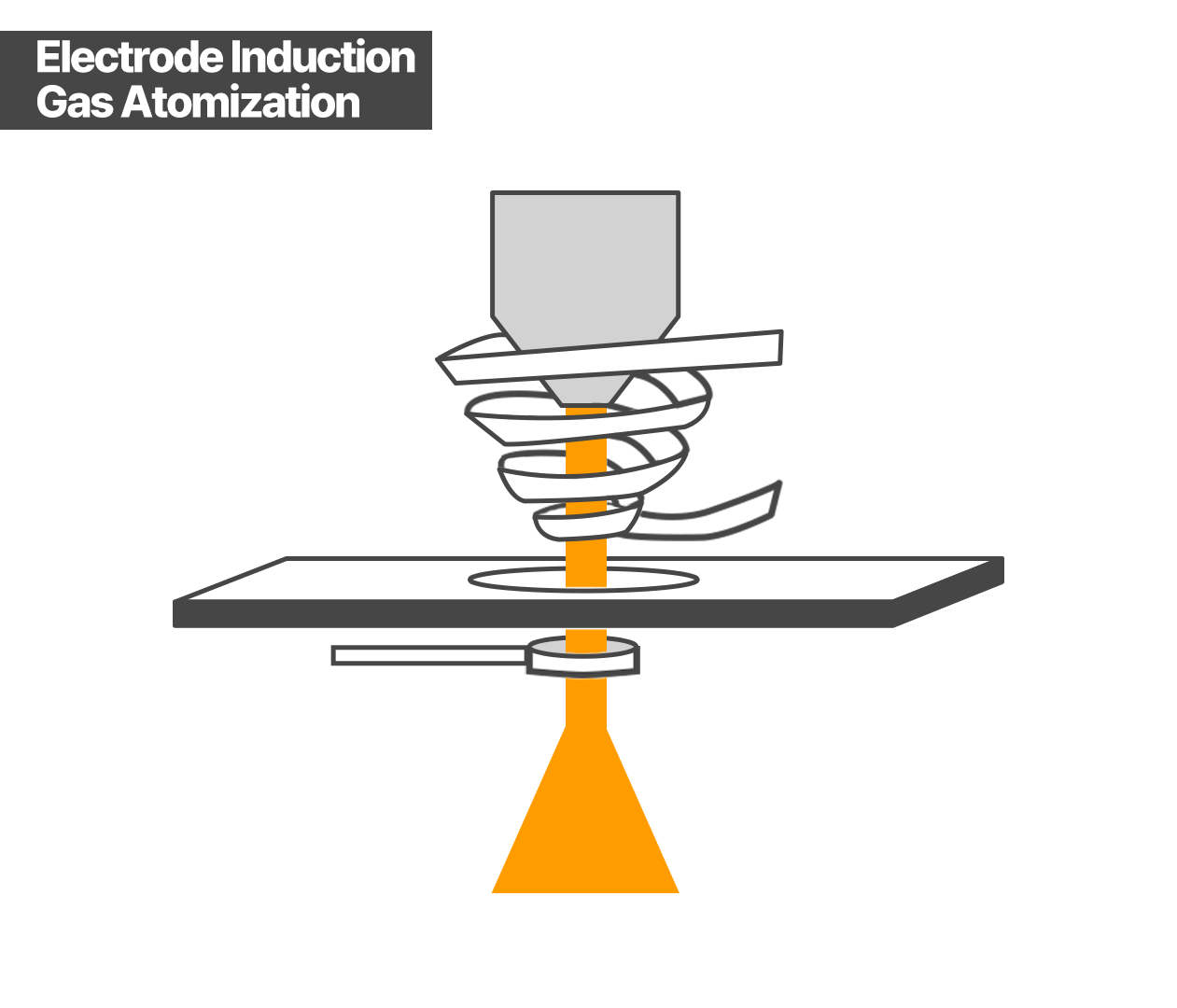

Electrode Induction–melt Inert Gas Atomization (EIGA) is a technique for powder manufacturing by gas atomization.

The process can be conducted ceramic-free and is therefore especially suited for reactive and refractory metals/alloys