FROM POWDER TO PERFORMANCE

HANA Advanced Material Technology

FROM POWDER TO PERFORMANCE

HANA Advanced Material Technology

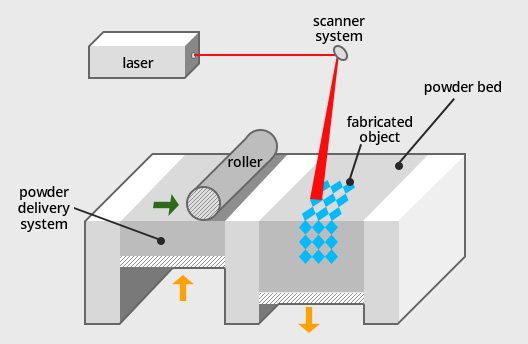

Selective laser melting is a popular technology to manufacture metal additive components. Using a laser as a heat source, SLM makes complicated components by selectively melting thin layers of metal powder. Normally, printings are made by the way of diffusing thin layers of metal powder to build plate composed of the same components with powders.

The selected parts in the powder layer fuse through the ground floor of CAD data, weld at the plate at the same time. Then, the build plate lay down as far as the thickness of the layer, repeat the process until the whole component is made.

Layer thickness of selective laser melting technology is much narrow than other technologies. As SLM has good dimension precision, it can control uniform microstructures. Cooling fast, it features superior mechanical characterization.